Production Line Inspection

Production Line Inspection

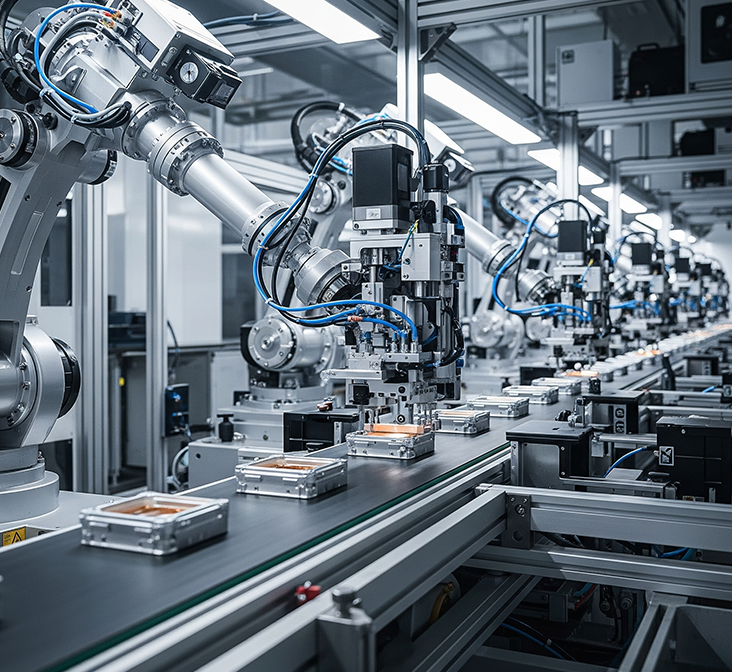

Production line inspection is a systematic approach that forms the backbone of the quality control process, involving the monitoring of products’ physical and visual characteristics at every stage of production. During this process, compliance with predefined quality standards is continuously monitored, and any deviations are detected in real time for immediate intervention.

The inspection process covers not only the final product but the entire production workflow. Products pass through specific control points along the production line, where they are evaluated according to pre-established parameters. These checks go beyond traditional visual inspections, utilizing advanced optical sensors, lasers and image processing.

Through production line inspection, defective production can be prevented at an early stage, which reduces scrap rates and increases overall production efficiency. At the same time, rework and waste costs are minimized, directly contributing to greater customer satisfaction.

This inspection process not only detects defects but also provides valuable data for continuous process improvement. These insights feed into quality management system, enabling ongoing development and optimization.